Tent Cabin In Omori

ARCHITECTS

Hune Architects

LEAD ARCHITECT

Kota Tamaki, Julia Li, Sei Hayashi, Koh Inami

ENGINEERING & CONSULTING > STRUCTURAL

Graph Studio

ENGINEERING & CONSULTING > OTHER

Haruka Shoji (Textile Design)

ENGINEERING & CONSULTING > ENVIRONMENTAL SUSTAINABILITY

Studio Nora

GENERAL CONTRACTOR

Akashoshin Kaihatsu Ltd

PHOTOGRAPHS

Yurika Kono

AREA

72 m²

YEAR

2025

LOCATION

Tokyo, Japan

CATEGORY

Houses

English description provided by the architects.

This is a two-storey timber house designed for a young couple and their two children.

Each family member has their own passions and rhythms, they wished for a home with a variety of places to retreat into and yet remain connected- so that their days could flow together without crowding into one another.

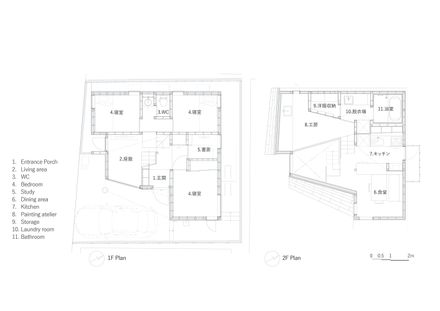

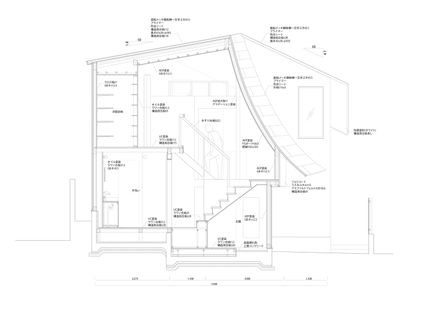

The site lies along a small lane branching from a narrow road that faces the railway tracks. The bedrooms are set in an L-shape in plan, staggered by half a level to follow the natural gradient between the front road and the rear of the plot.

Above the bedrooms, along the gentle climb of the staircase, a series of common spaces unfolds: a warm and cozy living corner, a dining area, a small painting atelier and a loft. These are gathered beneath four interlinked roofs, their forms draping softly over like a loose white cloth.

A central pillar lifts the roof to form a ridge, from which the four roofs, one of them curved, fold down towards the edges, letting the relationship between the roof and floor shift as you move through the building.

Climbing up the stairs from the entrance, the interior gradually opens, each step offering a new way of perceiving the roof line and the space beyond. Daylight slips through the cut edges of the roofs, grazing the curved roof form from the side, scattering colors that shift with the hour.

We imagine this house as a shared fabric draped lightly embracing this family, where each person can find a corner to call their own, yet all remain under the same gentle shelter, under the same roof.

To evoke the image of a tent-like, pliant roof in timber construction, we proposed forming a curved surface by laminating thin, bendable boards to a total thickness of about 40–50 mm.

After discussions with the contractor and testing through mock-ups, the system was finalized as three layers of cedar boards, each 300 mm wide and 15 mm thick.

Offsite, each board was carefully watered daily to soften the fibers, then bent over a curvature mould to follow the roof's designed geometry.

These pre-bent plies were transported to the site, staggered at the joints, and bonded together with screws and adhesive to form a unified 45 mm-thick curved laminated roof.

Measurements with MEMS acceleration sensors, conducted both in the factory and on site, showed that compared to a single 15 mm board, the 45 mm laminate achieved approximately 2.5 times higher natural vibration frequency.

This confirmed that the assembly provided out-of-plane bending stiffness equivalent to that of a solid 40 mm board, while still preserving the lightness and pliant impression of fabric gently stretched into form.