OngAng 3D Concrete Printing Bridge

ONGANG 3D CONCRETE PRINTING BRIDGE

Akarin Somkijrungroj , Kitti Kitsirikul , Sumeth Lekthai

LEAD ARCHITECT

Akarin Somkijrungroj , Kitti Kitsirikul , Sumeth Lekthai

GENERAL CONTRACTOR

Eps

DESIGN TEAM

Chaiwat Jirawijakkhana

ENGINEERING & CONSULTING > STRUCTURAL

Cpac Cs

TECHNICAL TEAM

Kritsada Sisomphon,passarin Jongvisuttisun, Patiphat Jiramarootapong

MANUFACTURERS

SCG

PHOTOGRAPHS

DOF Sky | Ground

AREA

40 m²

YEAR

2025

LOCATION

Bangkok , Thailand

CATEGORY

Infrastructure, Bridges

The Ong Ang Canal Bridge transforms a historic waterway into a piece of contemporary urban infrastructure that connects heritage and innovation.

Flowing through the historic core of Bangkok, the Ong Ang Canal once served as the city's defensive moat and later became a thriving artery of trade and daily life.

Over centuries, this waterway has shaped the rhythm of the communities along its banks.

The new pedestrian bridge reinterprets that living heritage through the language of water itself, capturing the canal's continuous motion in architectural form.

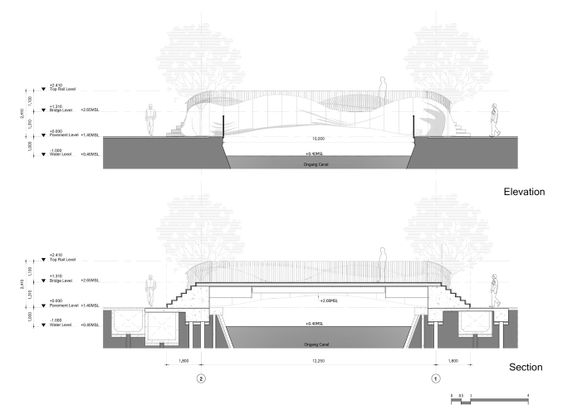

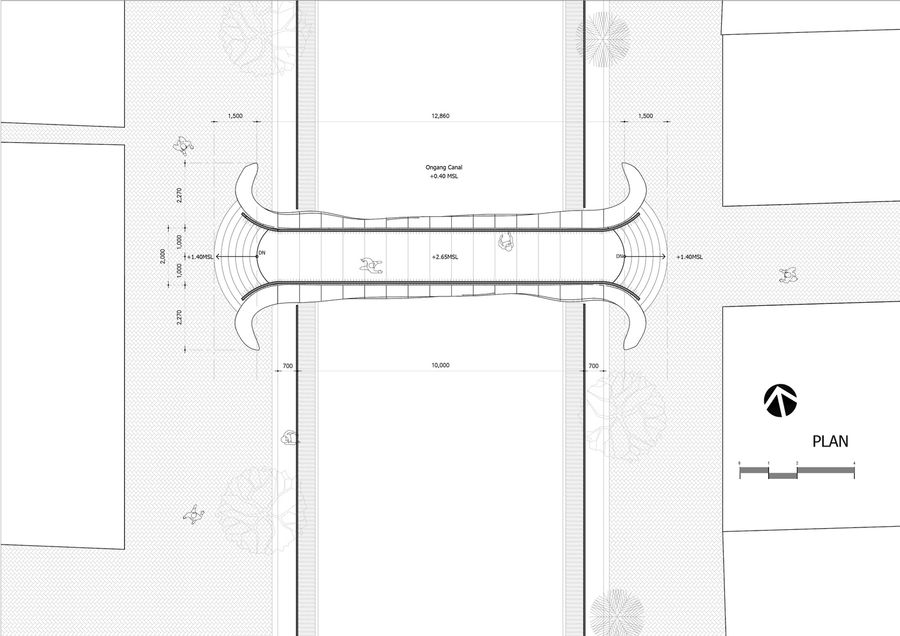

Located in Bangkok's dense old town, the narrow canal corridor and limited site access created constraints for both design and construction.

The project, commissioned under the Bangkok Metropolitan Administration's canal revitalization program, was envisioned as a compact landmark that could enhance mobility while minimizing impact on the surrounding community.

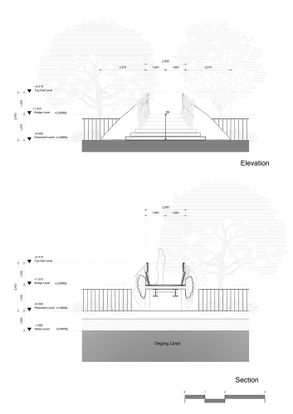

The bridge draws inspiration from the spiral of a wave—rising, folding, and dissolving into the walkway as if caught mid-motion.

Its sculptural silhouette appears to hover above the canal, symbolizing the connection between the two banks and their intertwined stories of culture and everyday life.

The fluid form was developed to echo the canal's natural rhythm while softening the visual weight of concrete within the tight urban fabric.

Beneath the crest, soft undulations reflect the play of light and water, giving the bridge a quiet sense of movement.

Every element of the bridge was 3D-printed in concrete, marking one of Thailand's first applications of large-scale digital fabrication for public infrastructure.

The project employs LC3 concrete, a low-carbon mix that replaces part of the cement with calcined clay.

Beyond its sustainability, the material carries cultural resonance—Ong Ang has long been a center of pottery and earthenware trading.

By transforming the "story of clay" into a structure, the bridge connects local craft heritage with modern construction innovation.

Reinforced with High-Performance Concrete (HPC), the printed components serve as both deck and balustrade, achieving a live load capacity of 500 kg/m².

Given the limited access, the bridge was prefabricated off-site and divided into 19 modular segments, each weighing about 1.5 tons.

Installation was completed within a single day using a small crane, reducing disruption and demonstrating the efficiency of the modular system.

A steel railing reinterprets the Thai Kranok motif as slender, tapering lines that merge with the surroundings.

From afar, the bridge reads as a fluid concrete ribbon; up close, it reveals subtle rhythms that guide movement across the span.

Situated at a key pedestrian link along the revitalized canal, it strengthens connectivity, invites gathering, and contributes to the area's renewed vitality.

The Ong Ang Canal Bridge illustrates how urban infrastructure can combine craftsmanship, sustainability, and technology while enhancing public mobility and revitalizing the canal-side public realm.

It redefines the canal as a living civic landscape—encouraging pedestrian activity, local commerce, and community gathering, while demonstrating how small-scale infrastructure can carry cultural meaning and connect Bangkok's historic fabric with its evolving urban future.