University Catholic Stadium Modernization Project

ARCHITECTS

Idom

ARCHITECTS AUTHORS

Borja Gómez, César Azcárate

ACOUSTICS

Idom

ENGINEERING

Wsp

PROJECT MANAGEMENT

Wsp

FACADES

Idom-mia

INDEPENDENT STRUCTURAL REVIEWER

Spoerer Ingenieros

INDEPENDENT ARCHITECTURE REVIEWER

Arquigestión

COLLABORATORS

Carlos Jose Vial Larraín, Cristian Lange, Francisco Javier Ruiz De Prada, Javier Dávila, Laudis Acosta, Rosaina Ivelisse, Carlos Castañón, Antonio Villanueva, Sergio Arús, Clara Guzman, Julio Fernández, Mario Torices, Felipe Gaona Moreno

COLLABORATING ARCHITECTS

Agostina Sambataro, Carmen Prada, Clara Guzmán, Diego Rodriguez Segura, Felipe Vergara Galleguillos, Fernando Garrido, Jose Manuel Pando De Prado, Manuel Bouzas Barcala, María Francisca Navarro Valenzuela, Samuel Araneda, Simón Lucas Morgado, Tomás Santiago Pérez.

MANUFACTURERS

ChileSeating

PHOTOGRAPHS

Cristóbal Palma

AREA

39592 m²

YEAR

2025

LOCATION

Las Condes, Chile

CATEGORY

Stadiums, Renovation

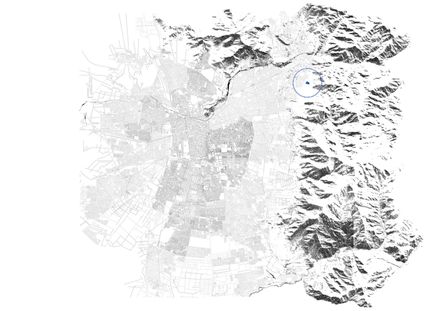

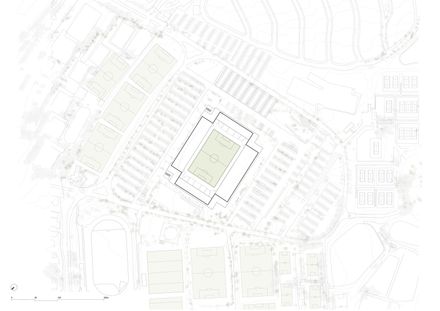

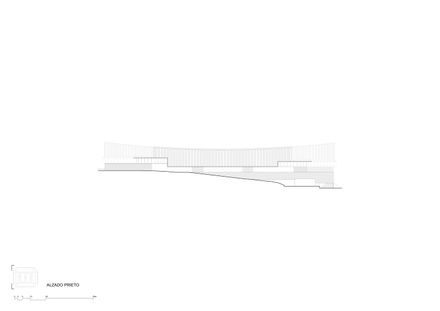

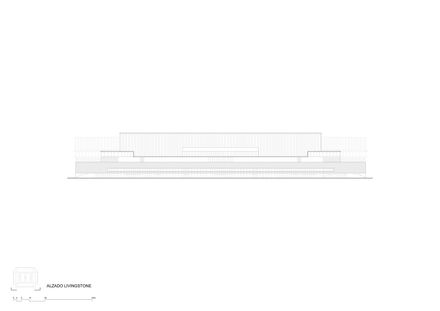

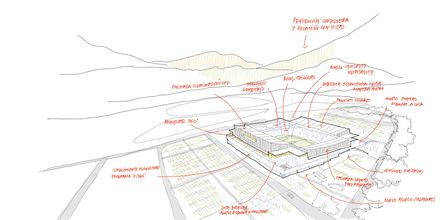

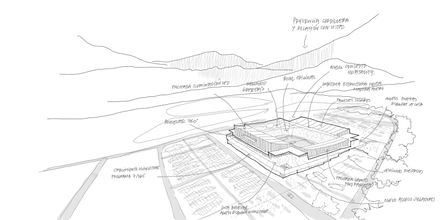

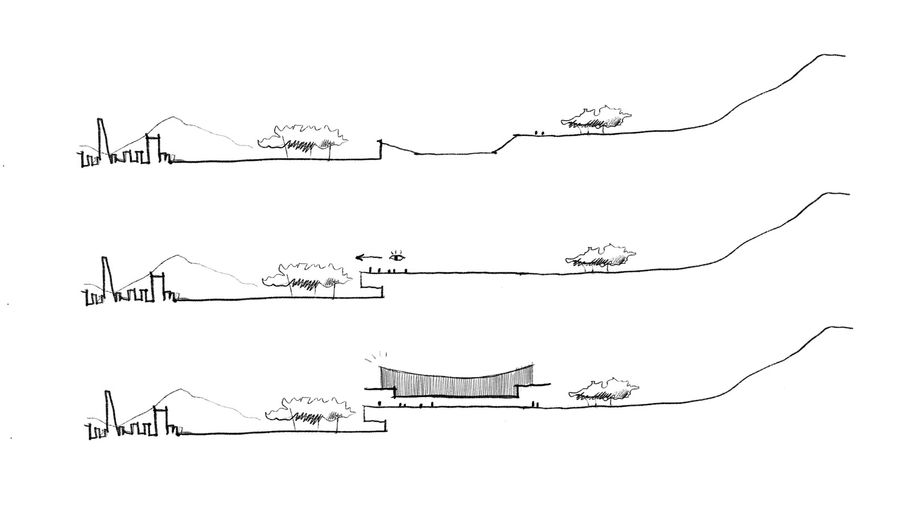

The San Carlos de Apoquindo Stadium (currently Claro Arena), inaugurated on September 4, 1988, is located in the Las Condes municipality of Santiago, Chile, on a sloping site towards the city, between the mountains and Manquehue Hill.

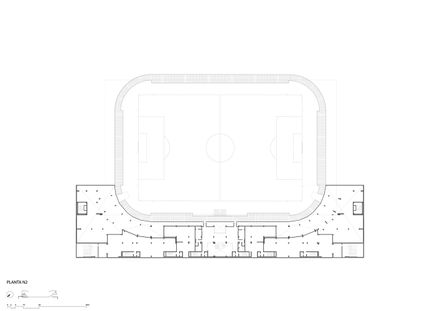

The original design featured a partially buried configuration, with differentiated access points between the eastern side (Fouilloux) and the western side (Livingstone).

In response to the need to increase capacity from 12,000 to 20,000 spectators and modernize the infrastructure, the club held a competition to transform the stadium into a space in line with contemporary football standards.

The new design had to meet technological, sustainability, comfort, and hospitality requirements, as well as allow for continuous use beyond matches, turning it into a multipurpose building.

The project, developed by IDOM, proposes a rational, efficient, and sustainable stadium, with attention to climate, energy, and comfort.

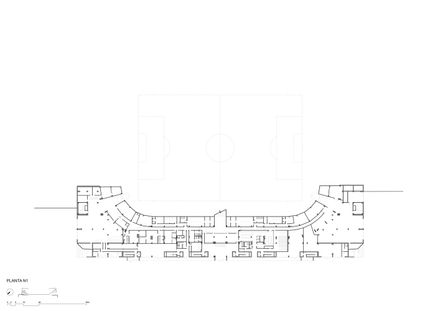

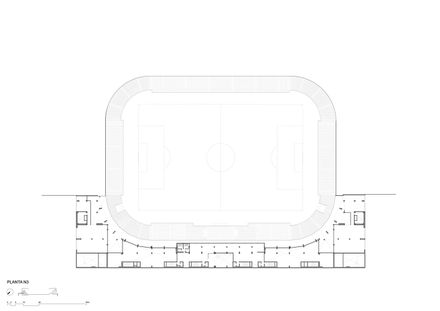

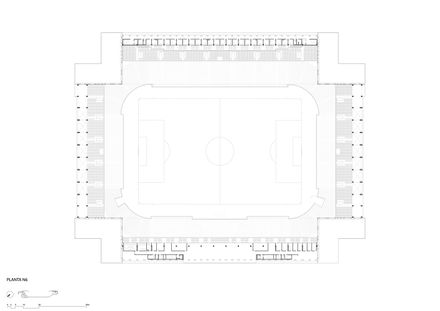

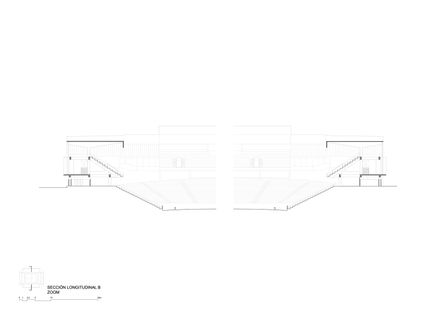

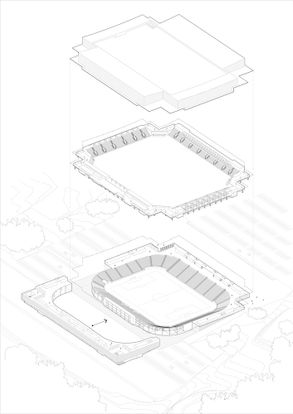

The original stands are preserved almost intact, upon which a perimeter boulevard at the Fouilloux level is constructed to connect all areas.

Below this boulevard, the old stadium remains, while above it rises a lightweight and permeable structure that houses the expansion.

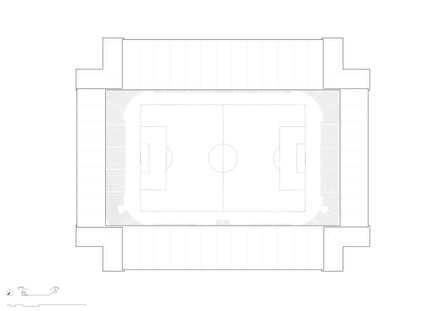

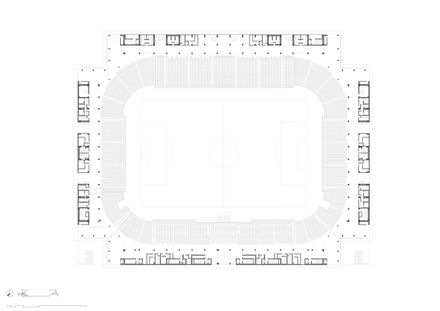

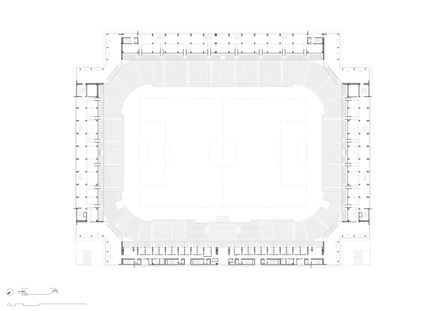

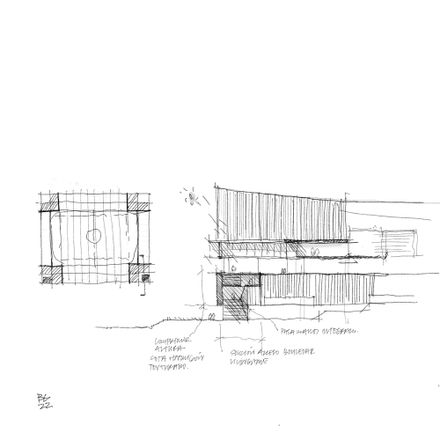

The layout adopts a rectangular geometry, optimizing sightlines and functionality. The corners become unique spaces that mark access points and offer multipurpose rooms with views of the landscape and the field, usable for both matches and other events.

The original stands retain 95% of their sightlines. New galleries for the general public and boxes are placed above it.

In Livingstone, the expansion develops both below and above the boulevard, integrating locker rooms, press rooms, technical areas, premium hospitality, and media spaces.

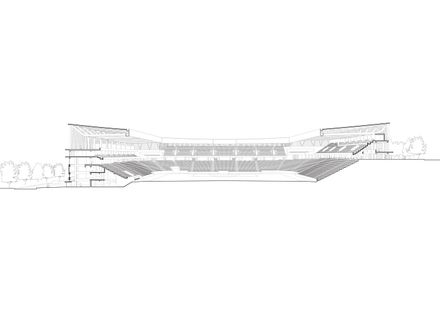

The structure maintains the original concrete, healthy and functional, minimizing interventions. The expansion is articulated around the existing bowl, with concrete beams and columns.

The corners incorporate mixed structures of inverted concrete and steel, optimizing forces and respecting regulatory heights.

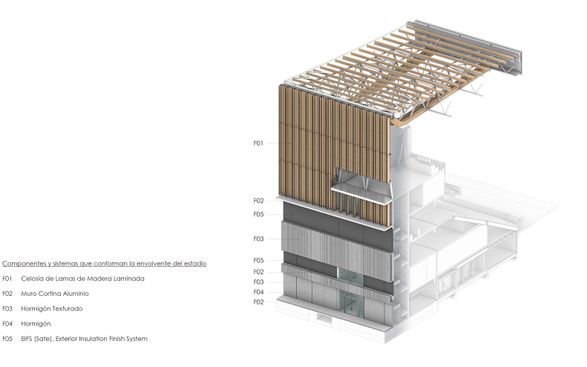

The stadium's envelope is designed to enhance environmental comfort in an open and non-air-conditioned space.

In the stadium expansion (from the boulevard level to the roof), Chilean radiata pine laminated wood is used in vertical slats every meter, integrating LED lighting.

Depending on the orientation, solar frames, acoustic panels, or openings for ventilation are incorporated. A concrete strip marks the start of the facade, serving as a finishing touch.

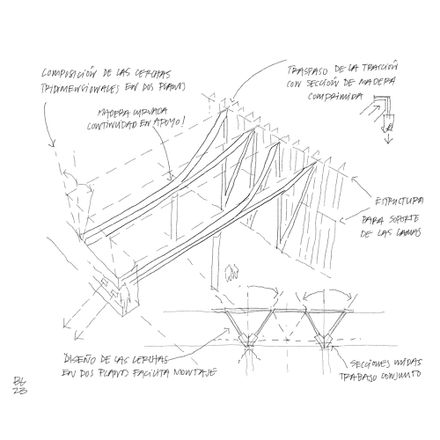

The roof, designed for seismic conditions, uses a mixed structure of wood and steel. In the back, laminated wood beams span distances of 17 m; on the sides, three-dimensional structures span up to 31 m.

The structural design optimizes the use of wood by taking advantage of its flexural properties to transmit forces while minimizing steel connections. The roof is completed with lightweight sheeting and TPO waterproofing.

Regarding sustainability, the project relies on cross-cutting strategies involving industrial partners in steel, plastic, wood, and energy.

Principles of reduction, reuse, and recycling are applied: building surface is minimized, energy and water consumption are optimized, the existing concrete structure is reused, and materials such as steel from the old roof and plastic from the seats are recycled.

Additionally, 1,600 m³ of Chilean laminated wood is utilized, capturing more than 1,500 tons of CO₂ and promoting local industrial development and circularity.