ARCHITECTS

Blue Temple

LEAD ARCHITECT

Raphaël Ascoli

LEAD TEAM

Raphaël Ascoli

DESIGN TEAM

Htoo Aung

TECHNICAL TEAM

Ko Zin

GENERAL CONTRACTOR

Housing Now

PHOTOGRAPHS

Aung Htay Hlaing

AREA

108 m²

YEAR

2025

LOCATION

Yangon, Myanmar

CATEGORY

Educational Architecture

English description provided by the architects.

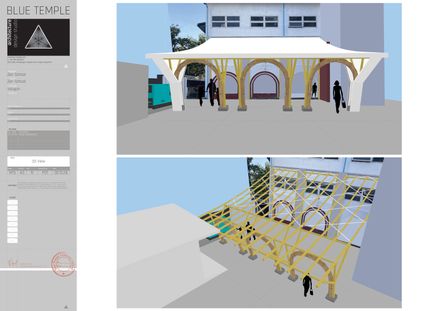

Tututat Shade Canopy is a compact architectural addition for a Reggio-inspired preschool in Tamwe, Yangon.

Conceived while our team was concurrently delivering post-earthquake housing in Mandalay. The canopy is conceived as an experimental exploration, using bamboo not for repetition or prefabrication but as a crafted, site-specific gesture that transforms the façade into an inhabitable extension.

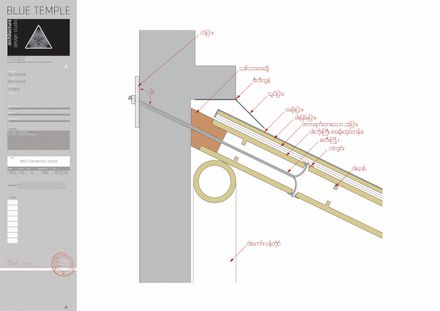

The concept begins not from the plan, but from the façade. Rather than "fitting" a structure into residual courtyard space, we surveyed the building elevation in detail and extruded its geometry outward.

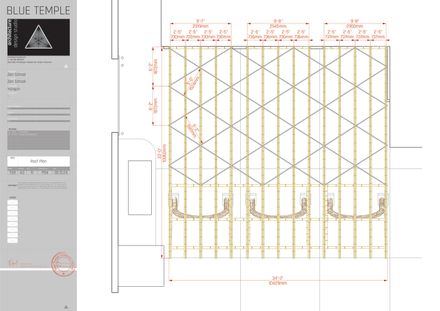

The new portico mirrors the existing arches and projects them as a sequence of long, curved bamboo ribs.

This approach anchors the intervention in the identity of the host building, allowing the addition to read as a natural extension rather than an imposition.

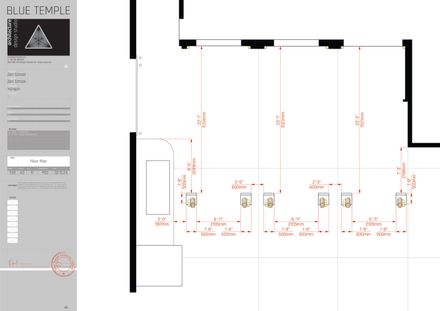

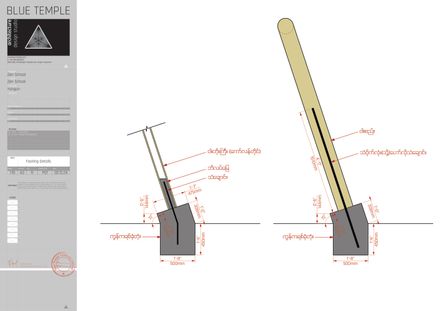

Geometry serves performance. By tucking bamboo members beneath projecting concrete beams and nesting new columns between existing ones, we choreograph water paths and minimize leak risk at the wall–roof interface.

The newly built threshold produces a shaded, well-ventilated "learning porch" for reading circles, music, phonics, and messy play—core to Tututat's pedagogy—while preserving rapid egress during earthquake high-alert periods.

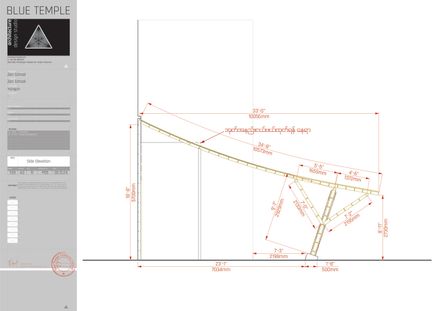

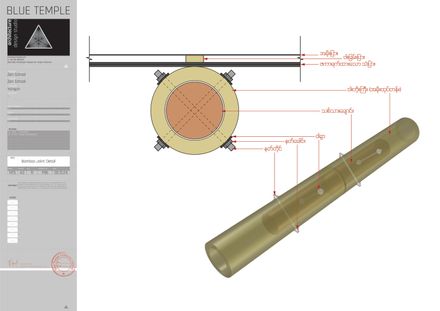

Structurally, the canopy adapts a tensile joint developed by Andry Widyowijatnoko and Rakhmat Fitranto Aditra (Institut Teknologi Bandung).

Their research on bamboo radial compression joints for tension/knock-down assemblies informed a connection that allows Dendrocalamus Giganteus bamboo to work in tension and keeps the system demountable.

In our build, each culm receives a custom-carved hardwood plug inside the internode with a carved-out tunnel to let through a metal cable; a steel-sleeved penetration manages local stress where the cable passes.

The cable itself loops around the culm—distributing load circumferentially rather than at a single point—then traverses the wall to an interior spreader plank that diffuses forces across the brick filling the wall.

These concealed details align material behavior with the constraints of an existing façade, privileging long-term durability over showmanship.

Materially, the project is almost entirely made of bamboo, fabricated with locally available components and assembled to minimize disruption to classes.

As a prototype, it demonstrates how precise survey, simple extrusion, and a carefully engineered joint can transform a façade into a small piece of everyday educational infrastructure—low-cost, light-touch, and beautifully nested.