Pomegranate Garden Micro Building

ARCHITECTS

Meaningless Arch, Tumu

LEAD ARCHITECT

Jiaojiao Miao (Meaningless Arch), Hui Luo (Tumu)

DESIGN TEAM

Jiaojiao Miao, Hui Luo, Jieying Chen, Bingbing Wen

VILLAGERS

Shihao Dai (Contractor), Fenzhen Chen, Zhengsheng Ye (Resident Support)

STRUCTURAL CONSULTANT

And Office, Zhun Zhang

PHOTOGRAPHS

Jiaojiao Miao

AREA

75 m²

YEAR

2025

LOCATION

Nanping, China

CATEGORY

Landscape Architecture

English description provided by the architects.

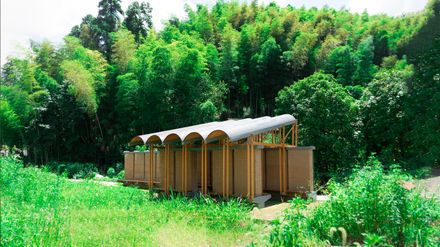

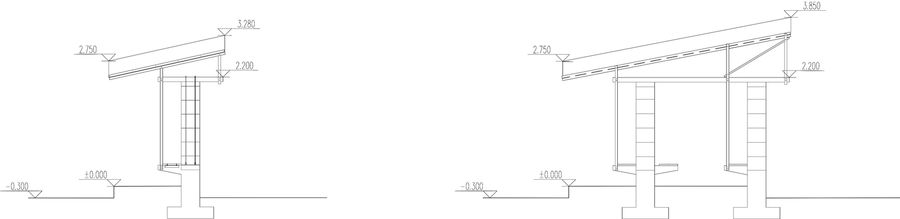

A wall prototype seeks a balance between structure and form, creating a resting space beneath a cantilevered roof.

Each unit is a small pavilion. The village is home to old rammed earth houses and aging craftsmen. Bamboo is abundant in the area, and bamboo factories are a local industry.

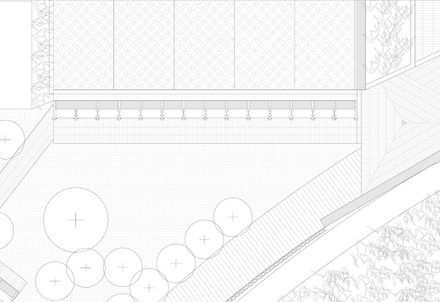

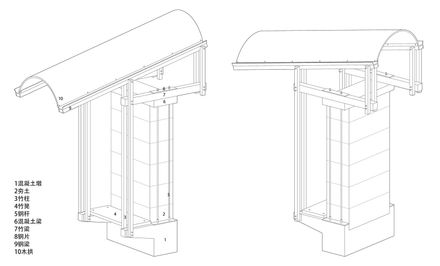

Concrete, wooden formwork, and steel are readily available and sustainable materials. The design prioritizes materials, creating a symbiotic dance of diverse materials. Concrete piers lift the rammed earth walls, which in turn lift the bamboo beams and columns. The bamboo, concrete beams, and steel poles stabilize the earth walls, and then lift the steel beams and wooden arches.

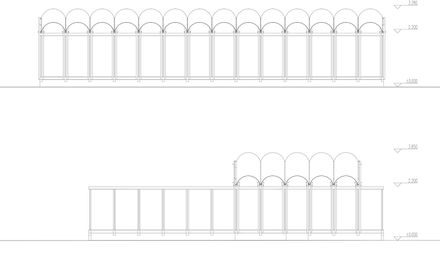

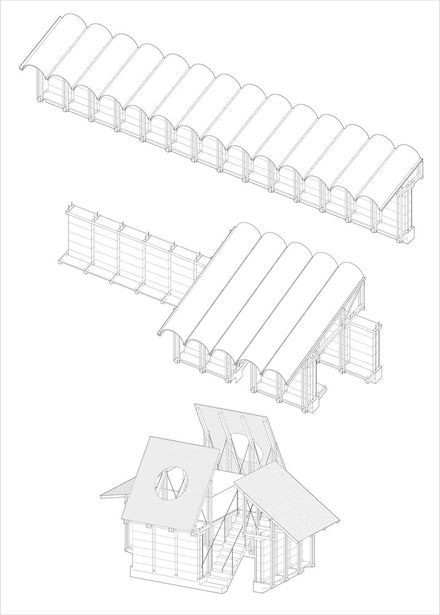

The arched crown cantilevers outward, creating a delicate balance. Each component is a structural element, providing appropriate force and form. The heaviness of concrete, the thickness of rammed earth, the lightness of bamboo, the fineness of steel, and the thinness and bulk of wood create visual tension through their interplay.A long corridor forms horizontally, a small pavilion longitudinally, and a second phase will also feature a vertical miniature tower.

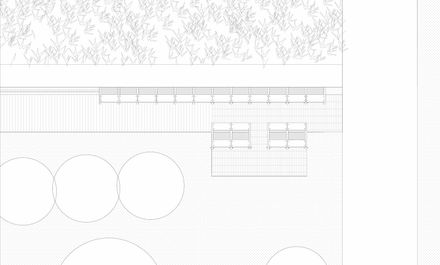

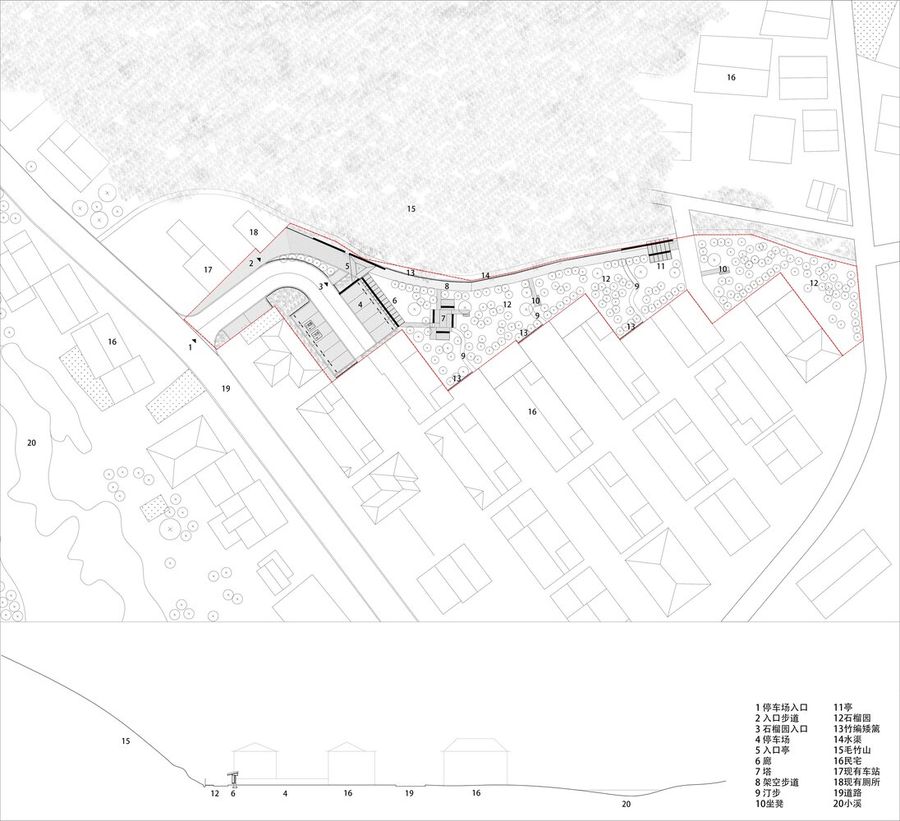

Together with the entrance pavilion, parking lot, garden paths, stepping stones, benches, low hedges, canals, and bamboo hills, once the pomegranate trees are planted, they will create a pleasant place for strolling, relaxing, and enjoying the pomegranate garden.

The continuation of force and form, the extension of space. The units, arranged in a row, connect to a long corridor, creating a repetitive and orderly pattern that forms the inner and outer boundaries of the pomegranate garden.

The wooden arched roof, coated with dark gray asphalt on the outside and bamboo membrane on the inside, appears dark on the outside and light on the inside, creating a sense of floating. A breeze flows through the roof and through the cracks in the wall, bringing a cool feeling to those who sit down.

Across from the house, a lush bamboo forest, the arched roof becomes a picture frame, framing the scenery before them. Light and shadow play across the blue brick floor and rammed earth walls, creating a lively atmosphere.

The overlapping of forces, the continuation of form, and the expansion of space. Unlike the "dangerous" horizontal corridors, the vertical pavilions are more stable. While the corridors offer limited space under the eaves, the pavilions enclose the space within the walls.

A wall unit is a point, the corridors are like one-dimensional space, the pavilions are two-dimensional, and the towers in Phase II are three-dimensional. The corridor serves as the boundary between the inside and the outside, the pavilion is the traffic node, and the tower is the spiritual height.

Concrete piers, rammed earth walls, and concrete beams were constructed wet-work on-site. The village boasts many old rammed earth houses, and the earth was sourced locally, mixing old and new soil. Bamboo products are a local industry, so bamboo beams, columns, wooden arches, steel beams, and bamboo benches were prefabricated and assembled on-site. Both materials and construction methods respect local characteristics, blending tradition with modernity.

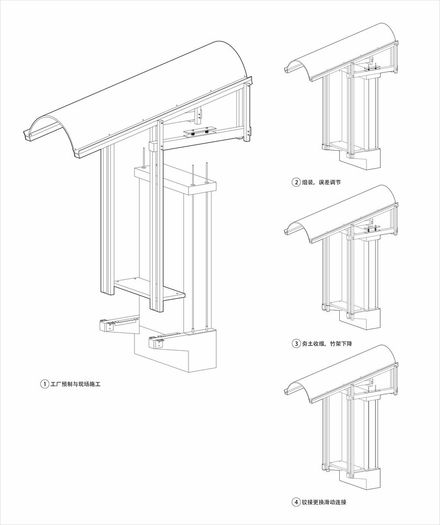

However, there are several potential errors:-1 Construction accuracy errors. On-site construction accuracy is poor, while prefabrication precision is higher, resulting in assembly errors. -2 Material performance errors. Rammed earth shrinks significantly after construction and persists for about six months. Concrete also shrinks slightly, and the articulation between the materials can lead to structural damage.

-3 Construction accuracy control. Despite the backward construction technology and rudimentary facilities in rural areas, improved construction accuracy is still needed to ensure the efficient execution of subsequent processes.

-4 Apply paint on concrete, waterproof paint on rammed earth, special waterproof and heat-insulating paint on bamboo columns and beams, special fluorocarbon paint on metal components such as steel poles and steel beams, and asphalt on wooden arches.

The solutions are: -1 The openings in the concrete beams are larger than the diameter of the steel rods to allow for the bamboo beams to adjust forward, backward, and left and right. -2 Adding springs to the upper ends of the steel rods to adjust the space for the rammed earth to shrink and fall.

The lower part of the bamboo column is connected to the concrete pier by a sliding connection, which will be replaced with a hinged connection after deformation is complete. -3 Customize the concrete wooden formwork, especially the concrete pier, with precise positioning and pre-embedded in advance.

Rammed earth is compacted and internal mesh is added to strengthen the connection. Protect the rammed earth during the pouring of the concrete beam. -4 Paint the concrete, waterproof the rammed earth, apply military waterproof and thermal insulation paint to the bamboo columns and beams, apply fluorocarbon paint to the metal components such as steel poles and beams, and coat the wooden arches with asphalt.