45 Industrialized Social Housing Units

ARCHITECTS

Vivas Arquitectos

LEAD ARCHITECT

César Vivas Millaruelo, Cristian Vivas Millaruelo

ENGINEERING AND CONSULTING > STRUCTURAL

Gendico

ENGINEERING AND CONSULTING > MEP

Arc Bcn

ENGINEERING AND CONSULTING > ACOUSTICS

Áurea Acústica

ENGINEERING AND CONSULTING > OTHER

Applus

ENGINEERING AND CONSULTING > QUANTITY SURVEYING

Dalmau-morros Tècnics

ENGINEERING AND CONSULTING > ENVIRONMENTAL SUSTAINABILITY

Societat Orgànica

LEAD TEAM

César Vivas Millaruelo, Cristian Vivas Millaruelo, Marc Obradó Cebada, Raül Benítez Margalef

PHOTOGRAPHS

José Hevia

AREA

4569 m²

YEAR

2024

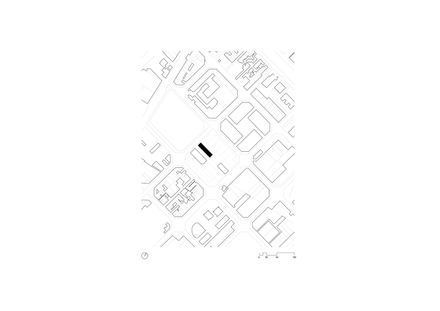

LOCATION

Barcelona, Spain

CATEGORY

Social Housing

English description provided by the architects.

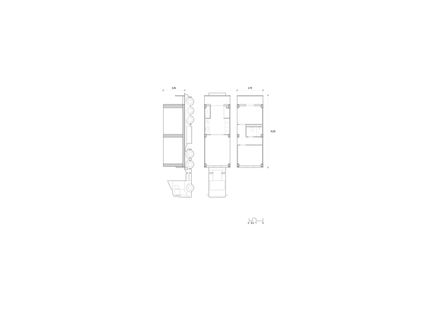

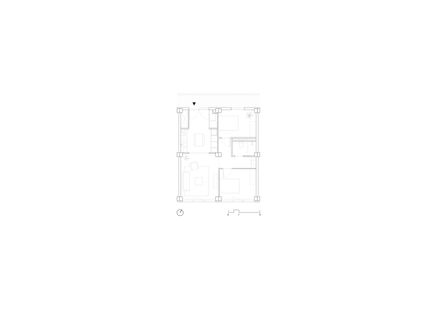

The project consists of the construction of 45 officially protected housing units, each with 2 bedrooms, distributed in an 8-story building with a total area of 4,465 m², with facilities on the ground floor.

INDUSTRIAL ENVIRONMENT AND ADAPTABILITY

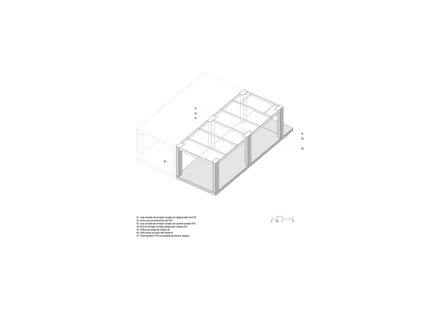

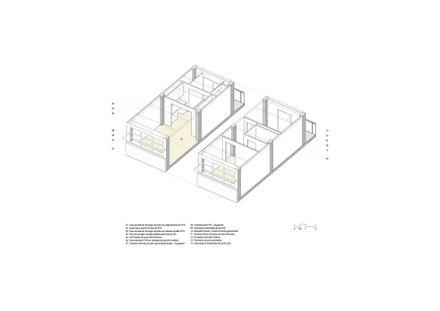

The proposal is presented as a residential building understood as a livable infrastructure with a clear and modular structure (prefabricated 3D modular construction), which allows for flexible use both now and in the future, with possible changes of use. The architectural proposal engages in dialogue with the existing textile factory, using a characteristic industrial language.

COMMUNITY TRANSITION

A gradient is proposed from the main road to the passage, the entrance porch, and the access walkways to the residences, understood as "exterior passages" at height.

These walkways resolve the transition between the community and the housing, fulfilling the dual function of filtering access and enhancing relationships among neighbors through the appropriation of these intermediate spaces.

Additionally, complementary community spaces are proposed on the ground floor and the roof of the building. These include multipurpose areas, a large community terrace with landscaped areas, and shaded porch spaces intended for neighborhood use.

CONSTRUCTIVE DUALITY

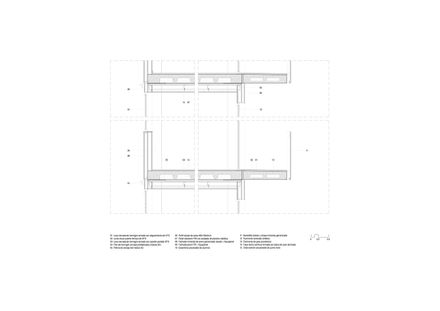

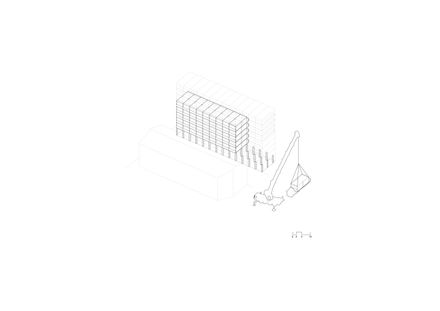

The construction combines "on-site" work for the foundation and the ground floor, with "off-site" manufacturing through 3D modules assembled in the factory, which include structure, enclosures, partitions, installations, finishes, and equipment.

OPTIMIZATION IN TIME, COSTS, AND MATERIALS

Due to the structural rationality of the floor distribution and the spans to be covered, a porticoed structure has been chosen using concrete columns and lightweight reinforced concrete slabs.

The project was completed with a total of 104 prefabricated 3D modules, transported and assembled on site in just 15 days, which significantly reduced execution timelines.

Because all construction materials are prefabricated, timelines were optimized through precise planning, simultaneous execution with on-site work, and reduced transportation.

This also contributed to minimizing construction costs (light structure and reduced foundation), ensuring greater quality control (factory site visits), decreasing environmental impact during construction (optimization and waste reduction), guaranteeing the closure of the material life cycle at the end of the building's life, and improving safety and work comfort.

The prefabrication of all elements has ensured the execution and durability of the materials, allowing the project to be completed in a total time of just 13 months. The installations have been planned to minimize energy costs and maintenance.

The proper functioning of the installations was verified in the factory, and the modules were waterproofed on top to ensure proper transportation and assembly using a large-tonnage mobile crane.

The incorporation of renewable energies, such as individualized aerothermal and photovoltaic systems, is anticipated to guarantee energy efficiency.

SUSTAINABILITY

The building, with an A energy certification, combines passive and active strategies to reduce demand and consumption.

Its bioclimatic design optimizes climate control and incorporates efficient systems such as LED lighting, aerothermal, and photovoltaic systems to achieve nearly zero consumption of non-renewable energy.