Irrawaddy Flower Garden Classroom Buildings

ARCHITECTS

Simple Architecture

LEAD ARCHITECT

Jan Glasmeier

BUILDERS (VOLUNTEERS)

Elisa Bisek, Tami Forgo, Vincent Georg, Leo Huang, Büsra Küpeli, Jonathan Wiedemann (1st Project), And Linda Böhret, Yling Kirk, Julia Prudzienica, Lizzy Ramm, Leyla Scarlatella, Rungpairin Suttichote, Emma Vogel, Jonathan Weduwen, Harry Whittaker (2nd Project)

BUILDER (WORKSHOP)

Students From Harrows Int. School, Bangkok (1st Project) And Students From St. Andrews Int. School, Bangkok (2nd Project)

PARTNER

Help Without Frontiers Thailand, Socialarchitecture E.v., Spinningtop

GRAPHICS

Jonathan Wiedemann (1st Project), And Yiling Kirk, Lizzy Ramm, Jonathan Weduwen (2nd Project)

BUILDERS (WORKERS)

Pa Gee, Ban Yah, Cha Paw, Cha Moo, Eh Chu, Zo Eh (1st Project), And Pa Gee, Nei, Kra Paw, Zo Eh, Cha Paw (2nd Project)

PHOTOGRAPHS

Jan Glasmeier, Leo Huang, Jonathan Wiedemann, Old Doors, New Ways, Isabell, Oliver Giebels

AREA

148 m²

YEAR

2025

LOCATION

Mae Sot, Thailand

CATEGORY

Schools

FIRST CLASSROOM PROJECT

Irrawaddy flower garden school is a school for burmese migrants under the tutelage of help without frontiers thailand.

The school is located about five kilometers from the thai-burma border and hosts 185 students from nursery/kindergarten to grade 8.

Following the latest military coup in burma on 1st february 2021, the number of students attending these mlc's has been steadily increasing.

Even though most of the schools are registered under the thai ministry of education (moe), the financial support infrastructure project is not.

This results in the erection of temporary structures, which are often very basic, mostly not sustainable, and almost never long-lasting.

This begets the issue of an insufficient number of classrooms within the school premises, resulting in the sharing of classroom space between different grades, or having to use the kitchen or outside area to conduct classes.

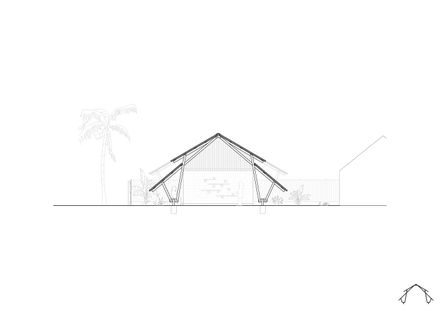

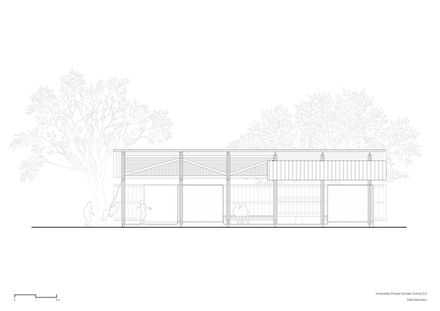

The first project in 2024 centered around the construction of two new classrooms. Together with a small group of architecture students, young architects, and local workers, the build took place over a duration of five weeks on site.

There were three types of A-frame modules that were designed to support the metal roof, forming the framework for both a lower and upper roof.

The spacing between the trusses also created an opportunity for the placement of low benches for the children to sit and play on.

A separating wall between the classrooms serves as a physical barrier, keeping noise levels controlled. Within the wall were embedded bamboo poles that formed shelves on either side of the classrooms.

SECOND CLASSROOM PROJECT

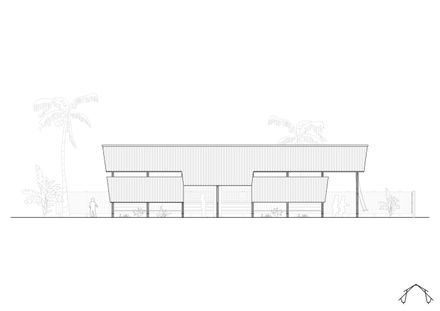

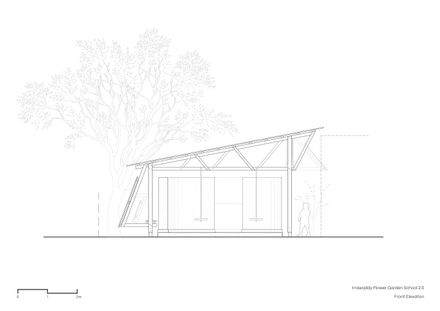

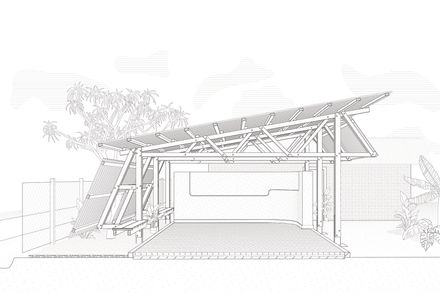

After completing the first classroom project in 2024, we returned to the school one year later to build a larger classroom building for the school's non-formal education program. The space requirements have been very different from the previous build.

During classes of the non-formal education program, school children from different grades gather in a larger space to learn English.

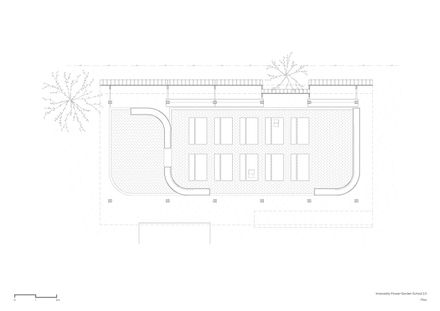

The new classroom has space for fifty students. At the entrance, the building hosts a small reception area for students to gather.

The site, located between the perimeter fence/ public canal and an existing small office building, had a difficult, narrow shape. Before starting with the excavation, we had to dig out the foundations of an old building.

Roots and trees along the fence were limiting the width of the building to 5.00meters. Like the project in 2024, we were able to complete the classroom construction in a period of five weeks.

The project is in contrast to the type of architecture glimpsed in schools or at work due to the different climate, culture, and way of construction. At the project's inception, site visits to the school were arranged to observe how lessons were conducted.

This then formed the basis of the design concept by gathering inspiration from the site and analyzing the users' space utilization. The design and planning were completed within the first few days.

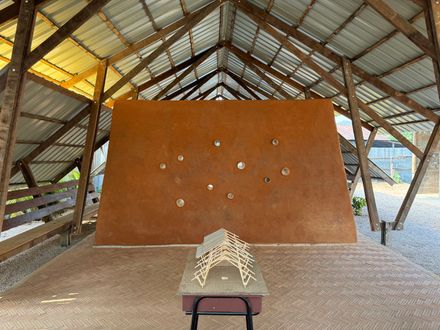

Meanwhile, adobe bricks for the wall were being produced on site, in close collaboration with local workers. Through this engagement, many new techniques and building knowledge were exchanged and shared.

The majority of the material used was locally sourced, in consideration of producing a building that was environmentally sustainable.

The timber used, for instance, was second-hand teak wood from a local lumber company that recycles used wood. Due to the nature of recycled wood, the pieces often came in irregular sizes.

This meant that the design had to be modified or adjusted on site, in a way that ensured it still met the overarching design intent.

The result of this was even more satisfying, having overcome the constraints to adapt and achieve a unique design.