ARCHITECTS

Michael Hansmeyer, Studio Benjamin Dillenburger

CONSTRUCTION

SIKA

SITE MANAGEMENT

Invias AG, Diego Casparin Nova Fundaziun Origen: Anja Diener

MANUFACTURERS

Sika

MASTER BUILDER

Zindel+Co. AG, Nico Russi Battaglia Bau AG (Uffer Gruppe), Sascha Pittet

BUILDING PHYSICS

mk bauphysik

LIGHTING PLANNING

Tokyoblue GmbH

ELECTRICAL SYSTEMS

TGA Solutions GmbH, Markus Furer

ELECTRICAL INSTALLATION

Elektro Savoldelli, Claudio Savoldelli

LIGHTING

Cavegn AG

FACADE CONSTRUCTION

Bieri Tenta AG, Richnerstutz

STRUCTURAL ENGINEERS

Conzett Bronzini Partner AG

CARPENTR

Poltera Holzbau AG

PHOTOGRAPHS

CheWei Lin, Nijat Mahamaliyev, Birdviewpicture, Benjamin Hofer, Benjamin Dillenburger and Michael Hansmeyer, Andrei Jipa, Girts Apskalns

YEAR

2025

LOCATION

Surses, Switzerland

CATEGORY

Watching Tower

Project Description - Tor Alva ("The White Tower") is the world's tallest 3D-printed building in the Alpine village of Mulegns, Switzerland. Designed by Benjamin Dillenburger and Michael Hansmeyer for the Origen Cultural Foundation, the tower reimagines Mulegns' cultural legacy through architecture.

It stands as a beacon in the village and functions as an immersive performance space. At the top of the White Tower is a cupola theater enveloped by a forest of filigree branching columns - a breathtaking venue above the village rooftops.

With its spectacular architecture and ground-breaking technology, the tower demonstrates the possibilities that computational design and digital fabrication offer the fields of architecture and construction.

These include not only economic and ecological advantages, but they allow for an elaborate non-standard architecture with a rich variety of forms.

The project serves a dual purpose: to create a one-of-a-kind performance space that merges architecture, culture, and science, while also revitalizing a village confronting structural challenges.

Additionally, it showcases the interdisciplinary research in architecture, structural engineering, and material science from ETH Zurich, advancing digital building practices that foster innovative, rich, and sustainable environments.

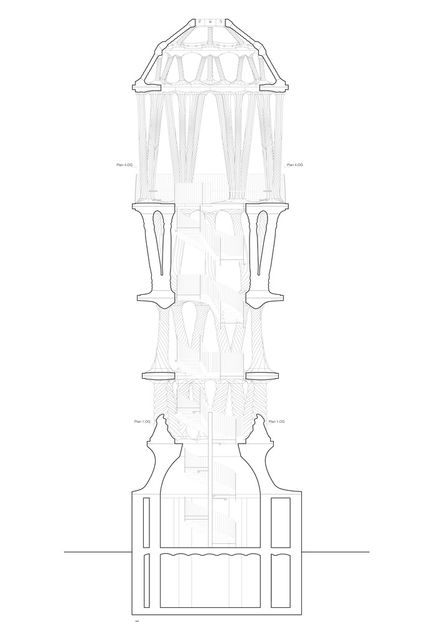

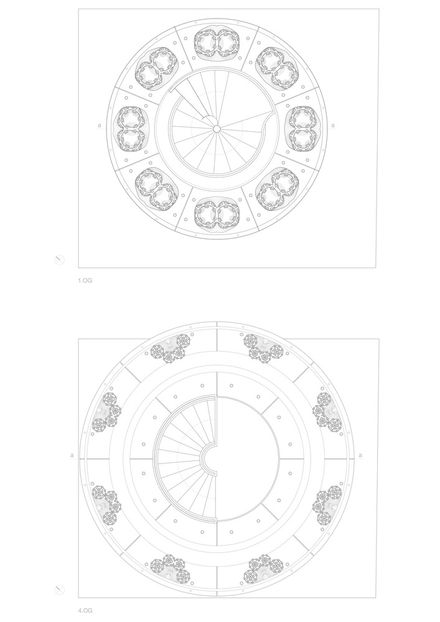

Architecture - The White Tower comprises 32 unique 3D-printed columns. Each column is articulated with a bold array of forms and intricate ornamentation across multiple scales.

Robotic fabrication masterfully plays with the material's behavior, establishing a unique ornamental language that gives the structure a mysterious, captivating presence and reveals a novel tactile surface quality.

This new digital craftsmanship recalls the artistry of Baroque builders in Grisons, bridging historical traditions with future innovations.

As visitors ascend the central spiral staircase, they encounter atmospherically dense spaces: dark chambers enclosed by massive columns lead upward to sunlit, open areas where slender, intertwined columns support a filigree dome.

The vaulted performance space, with its central stage, is surrounded by 32 seats. Guests enjoy breathtaking views of the village and the majestic Alpine landscape of Val Surses. At dusk, the White Tower transforms – its striking openings glow like a lantern, making it appear as a beacon along the historic Julier Pass route.

Research and Innovation - The White Tower showcases groundbreaking advancements in computational design, digital fabrication, structural engineering, and material science, all aimed at more sustainable construction.

These pioneering developments in architecture were made possible by intense collaborative and interdisciplinary- nary work with domain experts in structural engineering, materials science, and robotics, who all contributed with innovations from their respective fields to make this project possible.

Technical innovations include the structural use of 3D-printed concrete with thin-walled, material-efficient components, as well as modular construction for future reuse.

The White Tower is the world's first multi-story building to use fully load-bearing 3D-printed columns with reinforcement integrated during the printing process.

In the newly developed 3D concrete printing method, two robots collaborate: one extrudes concrete layer by layer into complex free-form elements, while the other inserts reinforcement between these layers.

This makes the 3D-printed structure fully load-bearing. Since concrete is only used where structurally needed, this formwork-free method significantlysignifi- cantly reduces material consumption compared to traditional casting techniques.

Designed for circularity, the White Tower features detachable connections, allowing it to be dismantled after its five-year use in Mulegns and reassembled at a new location.