Love Shack Multi-Functional Studio

ARCHITECTS

Second Edition

CLIENT

Julia & Will Dangar

ARCHITECTURE AND INTERIORS

Second Edition

PAINTING

Extreme Touch

MANUFACTURERS

506070, Cult, Hay, Homelife Furnishings:, Tom Fereday

BUILDER

Robert Plumb Build

LANDSCAPE

Dangar Barin Smith

STRUCTURE

Pmi Engineers

STYLING AND INTERIOR FURNISHING

Design Daily

JOINERY, DOORS AND WINDOWS

Cranbrook Workshop & Aah

CARPENTRY

Cedar Bespoke

PLUMBING

Joden Plumbing

ELECTRICAL

Map Electrical

ROOFING

Time To Change Roofing

LOCAL CRUSHING

Mcnamara Haulage

CONCRETE

Brooke Douglas

MECHANICAL

Crystal Air

RENDER

Lusso Venetian

RECYCLED TIMBER SUPPLY

Timber With Veins

METALWORK

Alsop Engineering

DOOR HARDWARE

Fritsjurgens, Halliday Ballie, Bankston X Edition Office

MECHANICAL FIXINGS

Rothoblaas

TAPWARE

Studio Xox & Salvaged

LOCATION

Sydney, Australia

CATEGORY

Mixed Use Architecture, Sustainability

Text description provided by architect.

The Love Shack is a built prototype for material reuse, design for disassembly (DfD), and small-scale functionality. Its conceptual framework is governed by resource efficiency and experimentation.

The core philosophy centers on minimizing waste while maximizing lifespan in an effort to reframe predetermined conceptions of how salvaged materials should look and perform.

Functionally, the studio space has the ability to transform from a bedroom to a living room to an office space, providing a flexible extension to the existing family home.

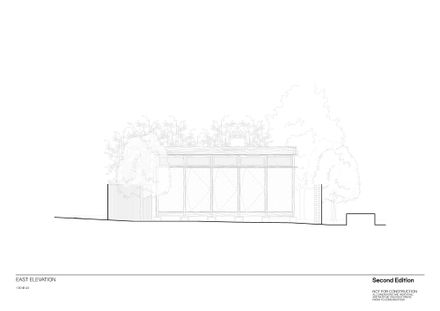

The facade facing the existing house includes operable solid doors that allow for privacy when closed and, when open, allow the pavilion to feel like an extension of the backyard.

Highlight windows provide natural ventilation year-round and even indirect light throughout the day.

Due to the rigid modular grid imposed on the triangular corner site, we were left with an irregularly shaped space where we chose to locate the bathroom.

The bathroom features a trapezoidal-shaped column centred in the room to house all the services and create programmatic delineation within a confined space.

The design approach centered on waste minimization includes material re-use, DfD; modularity, minimising material types, and dry fixing details. The 1.2m grid and 2.1m datum were derived from standard sheet sizes defined in the base logic of the plan and elevations.

The construction methodology commenced with concrete over pour dry placed footings. A footing was placed at every grid intersection to allow flexibility in the timber member sizes.

The timber joists and beams were procured from second-hand marketplaces and left rough, meaning there was no embodied carbon associated with transport and re-milling. After the structure had been erected, the prefabricated doors, windows, and facade panels were inserted.

The finishes internally and externally were driven by transforming local waste materials into high-quality, fit-for-purpose surfaces.

The external render was developed in collaboration with the renderer to create a mix that was textural, thin, suitable for outdoors, and incorporated high percentages of waste. We salvaged and crushed the marble locally.

Internally, the timber lining boards were sourced from tallowwood flooring in a Sydney home slated for demolition. The floorboards were carefully lifted by a deconstruction specialist.

Carpenters then refinished the boards so they could be installed as wall lining. The lights were made from the off-cuts of these lining boards.

The joinery is designed as a loose piece of furniture so that it can be removed with minimal impact should the client's needs change, and easily reused elsewhere. The piece is made using leftover single sheets of veneer.

Whilst some of the salvaged materials may have come at a lower upfront cost, the reality of the project's cost/value outcome is that it would have been more cost-effective to build using standard construction methodologies and virgin materials.

Our construction industry's infrastructure is geared for a linear building process.

Due to this, designing with salvaged materials generally takes more time, which increases the labour cost beyond the savings realised in the cost of materials.