Glass bottling Plant Cristalchile

ARCHITECTS

GH+A | Guillermo Hevia

MANUFACTURERS

Arrigoni, Atika, Chubretovic, GLASSTECH, Grasstech, Hunter Douglas, VIDROPAR

COLLABORATORS

Francisco Carrión G. (Arquitecto U.D.D.), Marcela Suazo M. (Desarrollo - CAD)

CLIENT

Cristalerías de Chile S.A.

TECHNICAL ADVISERS

Atika, Foster Weeler, Gerencia Técnica Cristalchile, Owens Illinois Co., Salfa Montajes S.A., Hunter Douglas Chile, Opendark S.A., Glasstech S.A.

MATERIALS

Estructura de pilares de hormigón prefabricados, vigas y cerchas metálicas; cubiertas y revestimientos paneles metálicos prepintados con aislación; radieres de hormigón y cristal serigrafiado.

CONSTRUCTION

Salfa S.A.

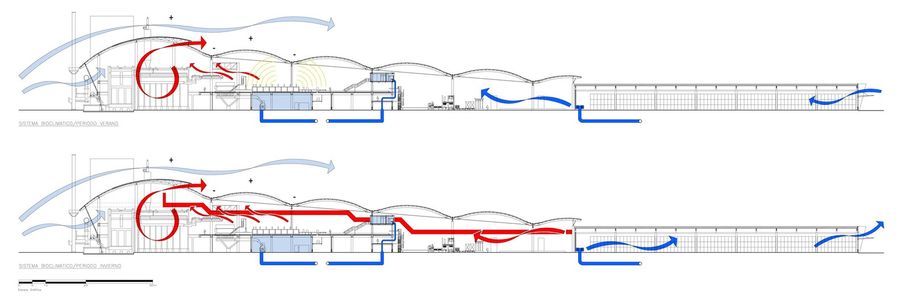

BIOCLIMATIC

BIOTECH Chile Consultores Ltda

LIGHTING

OPENDARK S.A.

PHOTOGRAPHS

Felipe Camus

SUPERFICIE CONSTRUIDA TOTAL

50.000 m2

SECOND STAGE

2012

AREA

27500.0 m²

PLOT AREA

27há

YEAR

2006

LOCATION

Llaillay, Chile

CATEGORY

Bottling Point

GENERALITIES

The company CRISTALERIAS DE CHILE S.A., has built the first stage of a new Cristalchile Glass Container Plant - Llay-Llay of approx. 27,500 m2 (Industry, offices and services) in a plot of 27 hectares, 85 kilometers north of Santiago, in the V Region.

After a visit to the land, analyzed the physical environment (urban location and access to Route 5 North), the climatic characteristics (winds, orientation) and verified the groundwater level, some design considerations emerged that we thought were important to consider for the success of this Project, those that are synthesized in the explanatory memory.

We think of the greatest importance the CORPORATE IMAGE with a vision of s. XXI for the Industrial Complex, image projected in the medium and long term, due to the size and complexity of the facilities and their growth, in a privileged location and a lot of presence. The new Industrial Complex reflects the business policy objectives of Cristalerías de Chile S.A. : Social, Technological, Commercial, Environmental and Development Policies.

THE DESIGN PROPOSAL

Within our objectives is the rationality of operation and future growth, optimizing technical and economic resources to evaluate the alternatives of construction systems, adapting the physical layout of the buildings on the ground (lay-out general) and according to environmental conditions required for this type of project in the place.

CORPORATE IMAGE

Due to the magnitude of the facilities, a contemporary architecture was proposed that is in harmony with the geographical environment.

An architectural solution of undulating lines for the main building, with the necessary heights for the different areas (as following the silhouettes of the nearby hills, seen from the road), incorporating the transparency in the facades by the use of glass with color screenprints blue and lines in metal, the light and the landscape are incorporated into the interior, in contrast to the buildings of Batch House (mixing plant) and the cellars of finished products, which are proposed more closed and with textures in the skins, giving movement to the facades, controlling both the height and the length of these volumes (image with contrasts in the day and night) and taking care of the interior characteristics of the enclosures and ventilation and lighting systems of the different areas.

The image of the Set is consolidated in front of the road, harmonized with green areas in the front and the perimeter of the land, and leaving the successive stages of "veiled" growth, to cushion its impact on the community and the place. The materiality of the buildings, responds to the objectives set and will consolidate their permanence over time.

CONCEPT

The preliminary Lay-out was reinterpreted by the Technical Management of Cristalerías de Chile S.A. and its Specialist Advisors, incorporating an aesthetic, functional, technical and architectural variable into the project. Due to the fact that the groundwater level is very shallow (approximately -0.80 m), the "base floor" of Furnaces and Regenerators could not be done in the traditional underground way for reasons of safety (possible flooding) and economic (high costs of protection systems and waterproofing), the only possible solution was on the surface.

In this way it was proposed to extend the base floor under the production line by locating the workshops, warehouses of raw materials (sand, glass), thus concentrating the production facilities and optimizing the occupation of the land. The Soil Mechanics Report was decisive to adopt an optimal structural and architectural solution, studying the feasibility of raising the production process to a higher level (approximately +6.70 m), looking for the technologies to mechanically lower the products up to the Warehouse warehouses on the floor +/- 0.00 m.

A perimeter ring of vehicular circulation is proposed, with a central safety and operation street that allows to optimize vehicular traffic, access to workshops and warehouses, and the general functionality of the plant (it also allows to separate the circulation flows of materials premiums and those of finished products). It is also a way to limit the initial urbanization of the land by reducing the impact of the construction in stages, without altering the operation and operation of the vehicles of the Plant.

ENVIRONMENTAL PROTECTIONS

A green belt is created in the boundaries (north, east and west) of environmental protection. The strong and constant winds in the place will impact the operation and the transfers of raw materials (possible waste).

This green belt is also necessary to reduce and dampen the noise pollution that the production system can generate affecting the immediate environment, thus taking advantage of a natural and aesthetic resource, transforming into a landscape contribution to the natural environment and improving the quality of life . Exotic and native species appropriate to the place, to the quality of the soils and to the environment (poplars, pataguas, quillay, etc.) are used.