IBA Timber Prototype House

IBA TIMBER PROTOTYPE HOUSE

PHOTOGRAPHS

Thomas Mueller, Ackermann GmbH Photo Jens Kestler, Hans Drexler

AREA

16.7 m2

PROJECT YEAR

2019

MAIN SPONSERS

ThüringenForst Rettenmeier Holding AG

PROJECT FUNDING

Bundesinstitut für Bau, Stadt- und Raumforschung Forschungsinitiative Zukunft Bau

Project Team

ICD Institute for Computational Design and Construction, Marta Doehler-Behzadi, Tobias Haag, Hans Drexler, Marie Deilmann, Geronimo Bujny, Anna Bulavintseva, Oliver Bucklin, Oliver David Krieg, Victor Rodriguez, A. Menges

Co Operation And Industry Partners

Klima und Umweltlabel Holz von Hier, Georg Ackermann GmbH, Universal Holzbau GmbH, Glaskontor Erfurt GmbH, Bauhaus-Universität Weimar, Ingenieurbüro Matthias Münz, Nils Holger Moormann GmbH, hofmann+löffler creativeinrichtungen GmbH

Text description provided by architect.

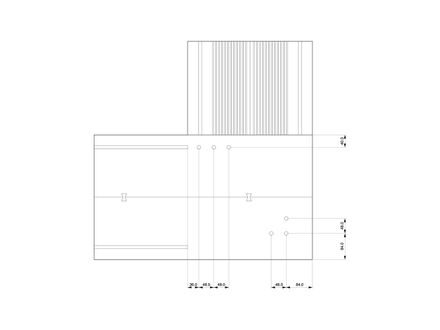

The IBA Timber Prototype House presents a new take on micro-architecture.

Effectively a log cabin turned on its side, it combines the benefits of traditional low-cost timber construction with advances in computational design and fabri- cation technologies.

The project explores a novel solid timber building system to economically create environmentally sound, architecturally expressive, mo- no-material building envelopes.

In contrast to the horizontal stacking of typical log construction, here the sol- id timber elements are arranged as staggered upright frames.

Thus the ver- tical elements are oriented in the strong direction of the wood which allows for sawing slits in the solid timber without comprising its structural capacity.

These thin slits serve as stress-relief cuts, which prevent the solid timber from splitting. This ensures dimensional stability and airtightness, both significant issues in traditional log construction.

At the same time, the slits are utilized as dead-air chambers, reducing thermal conductivity and increasing the insula- tion values of the material.

Digital fabrication is employed to produce high-pre- cision, airtight joints for connecting the timber elements without the need for any metal fasteners or adhesives.

The resulting, highly sustainable mono-ma- terial building system acts as structure, enclosure and insulation, achieving compliance with stringent German energy saving standards.

The fully integrat- ed computational design and fabrication approach allows for gently twisting and curving walls and ceilings.

They not only offer the possibility to maximize the ratio between available space and envelope surface, but also intensify the architectural experience of this unique micro-house.